You stand at the precipice of a significant operational enhancement: the implementation of a 72-hour repair window protocol. This document serves as your comprehensive guide, dissecting the intricacies, benefits, and challenges of adopting such a system within your organization. Think of this protocol not as a rigid cage, but as a well-oiled machine designed to inject efficiency and predictability into your repair processes.

The selection of a 72-hour repair window is not arbitrary; it represents a carefully considered balance between urgency, resource allocation, and customer satisfaction. You are, in essence, establishing a promise – a commitment to your stakeholders that issues will be addressed within a specific timeframe. This commitment acts as a powerful catalyst for improved performance.

Defining the “Repair Window”

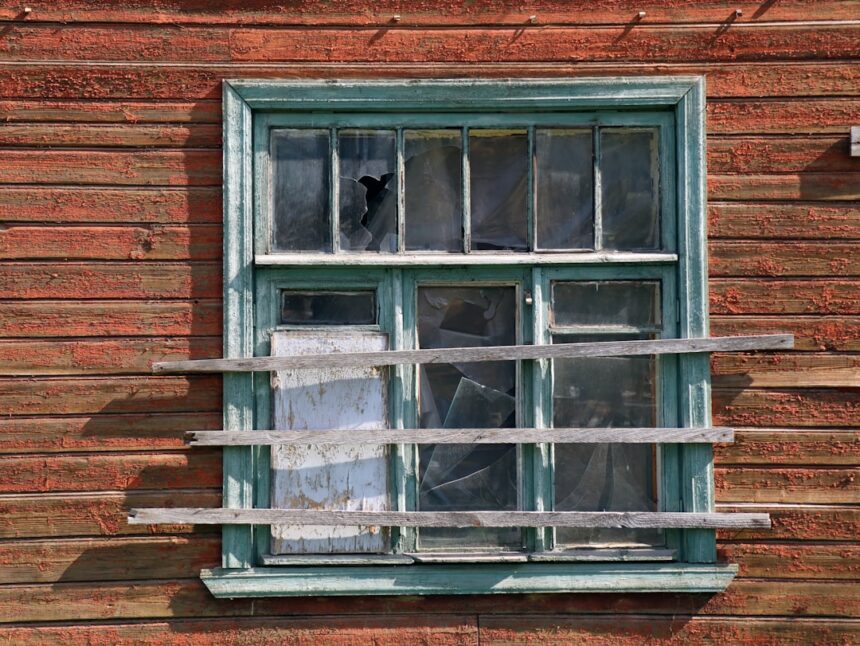

You must first understand what constitutes a “repair window.” It is the elapsed time from the initial reporting of a defect, malfunction, or service interruption to the successful restoration of the affected asset or service to its operational state. This definition is crucial for accurate measurement and accountability. It encompasses not just the physical repair itself, but also diagnostic time, parts procurement, and testing.

The Significance of Three Days

The 72-hour, or three-day, timeframe offers several strategic advantages. It provides sufficient time for complex diagnostics and the potential procurement of specialized parts, yet remains short enough to prevent prolonged downtime and customer frustration. Consider it a sweet spot in the continuum of incident resolution. Longer windows risk significant operational and reputational damage, while shorter ones may lead to rushed, suboptimal repairs or missed targets.

Impact on Stakeholder Perception

Your adherence to this window directly influences how your internal and external stakeholders perceive your operational efficiency and reliability. A consistent track record of meeting the 72-hour target builds trust and strengthens your brand. Conversely, frequent breaches can erode confidence and lead to negative perceptions. You are, in essence, building a reputation brick by painstaking brick.

The 72-hour repair window protocol is a crucial guideline in various industries, particularly in maintenance and service sectors, ensuring timely responses to equipment failures. For a deeper understanding of this protocol and its implications, you can refer to a related article that discusses best practices and strategies for effective implementation. To explore this further, visit this article.

Designing Your 72-Hour Protocol: A Blueprint for Success

Crafting an effective 72-hour repair protocol requires meticulous planning and a deep understanding of your operational landscape. This isn’t a one-size-fits-all solution; you must tailor it to your specific needs and constraints.

Defining Scope and Eligibility

Before embarking on implementation, you must clearly delineate the scope of the protocol. Which assets, systems, or services will be covered? Will it apply to all incidents, or only those deemed critical? For instance, a minor cosmetic repair to a non-essential asset might not necessitate a 72-hour response, whereas a critical system outage undoubtedly would. Establishing clear eligibility criteria helps prevent resource dilution and ensures focus on high-impact issues.

Establishing Clear Reporting Mechanisms

The clock starts ticking the moment an issue is reported. Therefore, you must have robust and easily accessible reporting mechanisms. This could involve an automated incident management system, a dedicated hotline, or a combination of both. The goal is to minimize reporting lag and ensure all necessary information is captured at the outset. Think of this as the starting gun for your race against the clock.

Workflow and Escalation Procedures

A well-defined workflow is paramount. You must map out every step from incident reporting to resolution, identifying responsible parties and their respective roles. This includes initial triage, diagnosis, repair execution, and final verification. Crucially, you need clear escalation paths for situations where the 72-hour window is at risk of being breached. This involves identifying thresholds and specifying who should be notified when these thresholds are approached or crossed.

Resource Allocation and Management

Implementing this protocol will undoubtedly place demands on your resources – personnel, tools, and spare parts. You need to assess your current capacity and identify any gaps. This might involve cross-training technicians, increasing inventory levels for critical components, or investing in new diagnostic equipment. Consider a “just-in-time” inventory system for frequently used parts, but also maintain a buffer for less common, critical items.

Communication Strategy

Transparency is key. You must establish a clear communication strategy for both internal teams and affected stakeholders. Regular updates on incident status, anticipated resolution times, and any potential delays are crucial. This proactive communication can significantly mitigate frustration and manage expectations, even when delays are unavoidable. Think of communication as the oil that lubricates the gears of your repair process.

Key Performance Indicators and Measurement

“What gets measured gets managed.” This adage holds particularly true for a 72-hour repair window protocol. Establishing clear Key Performance Indicators (KPIs) allows you to track progress, identify bottlenecks, and continuously refine your processes.

Mean Time to Repair (MTTR)

While your target is 72 hours, the Mean Time To Repair (MTTR) is a critical metric for evaluating overall efficiency. This represents the average time it takes to restore a failed system or component to full operation. You should be striving for an MTTR significantly below 72 hours, demonstrating a buffer for unexpected complexities.

First-Time Fix Rate (FTFR)

A high First-Time Fix Rate signifies efficient diagnostics and effective repairs. Frequent revisits to the same issue not only consume valuable resources but also negatively impact the 72-hour target. Invest in training and comprehensive diagnostic tools to improve your FTFR. Imagine trying to cross a river by building a bridge, only to have it collapse halfway through – a high FTFR means your bridge is sturdy from the first attempt.

Backlog Management

A growing backlog of unresolved issues is a clear indicator that your resources are stretched or your processes are inefficient. Regular monitoring of your backlog helps you identify trends and proactively address potential bottlenecks before they impact your 72-hour target. A controlled backlog is a healthy sign; an uncontrolled one is a harbinger of trouble.

Customer Satisfaction (CSAT)

Ultimately, the success of your protocol hinges on customer satisfaction. While internal metrics are important, external validation is paramount. Implement surveys or feedback mechanisms to gauge customer perception of your repair services. Their experience provides invaluable insights into the effectiveness of your 72-hour window.

Cost of Downtime

Calculating the cost of downtime for various assets helps you prioritize repairs and justify investments in preventive maintenance and faster repair capabilities. Understanding the financial implications of extended outages underscores the importance of adhering to the 72-hour window.

Overcoming Challenges and Continuous Improvement

Implementing a new protocol is rarely without its hurdles. Your ability to anticipate and overcome these challenges will determine the long-term success of your 72-hour repair window.

Resistance to Change

Human nature often resists change, even when it promises improvement. You may encounter resistance from technicians accustomed to older practices or managers hesitant about new reporting requirements. Address this by clearly communicating the “why” behind the protocol, highlighting its benefits, and involving key personnel in the design process. Champion the narrative of efficiency, not just compliance.

Data Accuracy and Integrity

The effectiveness of your metrics and analysis is entirely dependent on the accuracy and integrity of your data. You must ensure that incident reporting is accurate, timestamps are precise, and repair details are meticulously documented. Garbage in, garbage out applies here with full force.

Skill Gaps and Training Needs

The demands of a 72-hour window may expose existing skill gaps within your technical teams. Proactive identification of these gaps and the provision of targeted training are essential. This could involve upskilling technicians on new technologies, improving diagnostic abilities, or enhancing problem-solving techniques.

Spare Parts Availability

A common Achilles’ heel in repair operations is the availability of spare parts. Unexpected shortages can cripple your ability to meet the 72-hour target. Implement robust inventory management systems, foster strong relationships with suppliers, and consider strategic stockpiling of critical components. Think of your spare parts inventory as your ammunition – without it, your repair team is disarmed.

Scalability and Adaptability

As your organization grows or its operational landscape shifts, your protocol must be scalable and adaptable. Regularly review and refine your processes to ensure they remain relevant and effective. This is not a static document; it’s a living instrument that evolves with your organizational needs.

The 72-hour repair window protocol is an essential guideline for ensuring timely maintenance and minimizing downtime in various systems. For those interested in exploring the psychological aspects of how such protocols can impact team dynamics and stress management, a related article can be found on Unplugged Psych. This resource offers valuable insights into the mental health considerations that arise in high-pressure environments, making it a great complement to the technical aspects of the repair window. You can read more about it in this article.

The Long-Term Benefits of a 72-Hour Horizon

| Metric | Description | Target Value | Measurement Frequency |

|---|---|---|---|

| Response Time | Time taken to acknowledge a repair request | Within 2 hours | Per incident |

| Repair Completion Time | Total time to complete the repair from initial report | Within 72 hours | Per incident |

| First-Time Fix Rate | Percentage of repairs completed without follow-up visits | 85% or higher | Monthly |

| Customer Satisfaction Score | Rating of customer satisfaction post-repair | 4.5 out of 5 or higher | After each repair |

| Number of Delayed Repairs | Repairs not completed within the 72-hour window | Less than 5% of total repairs | Monthly |

| Parts Availability Rate | Percentage of repairs where required parts are available immediately | 95% or higher | Monthly |

By diligently implementing and adhering to a 72-hour repair window protocol, you are not merely adopting a new procedure; you are investing in a more resilient, efficient, and customer-centric operation.

Enhanced Operational Efficiency

The proactive nature of a timed repair window forces you to streamline processes, optimize resource allocation, and identify and eliminate inefficiencies. This leads to a smoother, more predictable operational flow. You replace reactive firefighting with strategic problem-solving.

Improved Customer Satisfaction and Loyalty

Customers value reliability and responsiveness. Consistently meeting a 72-hour repair window builds confidence, strengthens relationships, and fosters loyalty. Word of mouth, a powerful marketing tool, will work in your favor as satisfied customers laud your efficiency.

Reduced Downtime and Financial Losses

Minimizing downtime directly translates to reduced operational disruptions and mitigated financial losses. Every hour an asset or service is offline carries a cost, and your 72-hour protocol actively works to curtail this expense. It’s a direct impact on your bottom line.

Data-Driven Decision Making

The data collected through your protocol provides invaluable insights into your operational strengths and weaknesses. This allows for informed, data-driven decisions regarding resource allocation, training investments, and process improvements. You move from intuition-based decisions to evidence-based strategies.

Increased Employee Morale and Accountability

A clear protocol provides clarity and direction for your repair teams. Knowing their targets and having the tools and processes to meet them can boost morale. Furthermore, the defined accountability structure encourages ownership and a sense of shared responsibility for achieving the 72-hour goal. You are empowering your teams to succeed.

Implementing a 72-hour repair window protocol is a strategic imperative in today’s demanding operational environment. It’s a commitment to efficiency, a promise of reliability, and a foundation for sustained success. Approach it with meticulous planning, continuous improvement, and a steadfast dedication to excellence, and you will reap its manifold rewards.

WATCH NOW ▶️ WARNING: Your “Healing” Is Actually Avoidance (Stop Hiding)🚨

FAQs

What is the 72 hour repair window protocol?

The 72 hour repair window protocol is a guideline that requires repairs or corrective actions to be completed within 72 hours from the time an issue is identified. This protocol is often used in maintenance, safety, and compliance contexts to ensure timely resolution of problems.

Who typically implements the 72 hour repair window protocol?

This protocol is commonly implemented by organizations in industries such as manufacturing, transportation, healthcare, and facility management, where timely repairs are critical to safety, operational efficiency, and regulatory compliance.

What types of issues are addressed under the 72 hour repair window protocol?

The protocol generally applies to safety hazards, equipment malfunctions, compliance violations, or any defects that could impact operational integrity or safety. The specific issues covered depend on the organization’s policies and regulatory requirements.

What happens if repairs are not completed within the 72 hour window?

Failure to complete repairs within the 72 hour window can result in penalties, increased risk of accidents, operational shutdowns, or regulatory actions. Organizations may also need to document reasons for delays and implement interim safety measures.

How is compliance with the 72 hour repair window protocol monitored?

Compliance is typically monitored through maintenance logs, inspection reports, and tracking systems that record the time an issue was identified and when repairs were completed. Audits and reviews may also be conducted to ensure adherence to the protocol.